TOTAL WASTE TREATMENT

The HDI Range allows daily working time up to 24 hours. HDI equipment has two stages including a primary combustion chamber, with a hot-hearth construction, which ensures the total destruction of the waste. An integrated post-combustion system completes the process, to guarantee maximum gas turbulence, and ignite the gases which remained unburnt during the first combustion. These gases are maintained for a minimum of 2 seconds at temperatures from 900°C to 1200°C, thus ensuring complete incineration of its components (oxidation).

SOLID WASTE LOADING

The HDI series incinerators are designed for manual or automatic loading with hydraulic assistance. Loads of all types of waste are done through a front access, which reduces heat loss during loading.

Manual loading

Automatic Loading

LIQUID WASTE LOADING

The option for automatic loading by pneumatic assisted injectors, of liquid, muddy or pasty waste, allows loading of waste safely. One or more injectors are directed towards the center of the combustion chamber.

Liquids Injector

MANUAL DE-ASHING

Ash removal can be manual or automatic (optional). In manual mode, this involves emptying the tank or the bucket provided for this purpose, using a forklift. This can be done completely automatically.

AUTOMATIC DE-ASHING

The discharge located under the incinerator is separated from the combustion chamber by means of a hydraulically controlled ashes removal hatch. The ashes extraction operation is programmable and can be carried out before the start of a new cycle, or at the end of the cycle, X times a day, ..., of incineration. The ashes removal cycle from the combustion chamber has a selector to allow the ashes to be poured by gravity into bins arranged for this purpose.

FILTRATION OF EMISSIONS (FUMES)

There are different possibilities. From the incineration process, by pyrolysis or oxidation, the waste is transformed into fumes which must be treated. INFIGROUP offers all kinds of different filtration methods, up to the adapted dry treatment (ceramic ) which complies with CE standards.

- Fuel tank

- Door

- Combustion chamber

- Post combustion

- Post combustion duct

- Chimney

- Roof drop guard

- Washer ventilator

COMBUSTION HEAT RECOVERY

COMBUSTION HEAT RECOVERY

It is possible to add one of the 3 Energy Packs, which makes it possible to produce different types of energy, from the lost heat of the combustion.

Example of the recovery of the heat from combustion, into electricity

Energy Pack Power

The heat ofcombustion is used to feed an ORC (Organic Rankine Cycle) or a steam turbine, for self-consumption or resale to the national grid.

Energy Pack Heat

The heat of combustion is used to produce hot water or steam, for sanitary or industrial applications.

Energy Pack Cold

The heat of combustion is used to operate a cold by absorption system, for air conditioning or industrial refrigeration applications.

WASTE GRINDERS OR SHREDDERS

For large solid waste, we have a whole range of Grinders and Shredders, which allows to put the waste at an acceptable size into the incinerator.

SPECIFICATIONS

Any intermediate size between 100 kg/h and 3,000 kg/h can be made on request. Do not hesitate to contact us

HDI120

Containerized HDI120

ENVIRONMENTAL IMPACT

All of our solutions are fully CE certified, the highest standards in health and safety, construction, and the environment. INFIGROUP is committed to the environment and continues to develop the cleanest and best solutions for waste management.

INFIGROUP IS A MANUFACTURER

INFIGROUP is not an intermediary but is the designer and manufacturer of its equipment. You can therefore choose, according to your technical means and your internal skills, the scope of our service. We offer you from the simple provision of the solution from our workshop, to a full service of assembly, start-up on site, and staff training.

Being an international player in the waste treatment equipment industry, INFIGROUP owes its success to processes known for their efficiency, reliability, flexibility and ease of use. INFIGROUP sells its solutions to four continents, in partnership with an international network of agents, distributors, and technicians.

HDI INCINERATOR

CAPACITY: from 100kg/h up to 3 000 kg/h

Static Furnace

- Specific industrial waste

- Hazardous industrial waste

- Healthcare activity waste with infection risk

- Municipal solid waste (MSW)

- Miscellaneous waste

A SAFE AND PROVEN SOLUTION FOR THE TREATMENT OF SPECIAL SOLID, LIQUID OR SOGGY WASTE

- Capacity range from 100 kg/h up to 3 t/h, per incineration line;

- Waste heat recovery with LVH from 400 kJ/kg up to 12,000 kJ/kg

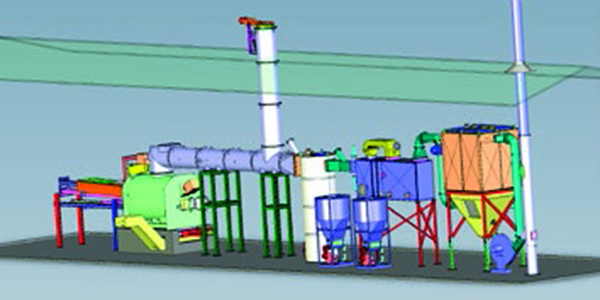

With a traditional design, waste treatment installations can consist of a static furnace, a post-combustion chamber and other items such as a boiler (heat exchanger) for steam production, possibly combined

- Several versions are available:.

- Manual, semi-automatic or fully automatic loading;.

- Manual or fully automatic de-ashing;<.

- Smoke treatment by wet washer or dry filter (ceramic).

The general principle consists in the combustion of waste at high temperature, between 900°C and 1 200°C, in the static furnace. The introduction of waste into the furnace is done according to the nature of the waste:

- solid waste is introduced by a loading skip, a receiving hopper and a feed pusher, and is introduced into the combustion chamber at 1 or several floors (at different heights). Pushing movements are then programmed according to the combustion analysis, thus bringing the waste down to the pyrolysis state from one floor to another, lower. These riddling therefore have the double object of pushing on the floor below and of stirring the waste in the pyrolysis state.

- Liquid and gaseous waste can be introduced at two levels, either into the rectangular body of the furnace, or directly into the post-combustion chamber via burners or specific injection nozzles. This proven process ensures complete destruction of hazardous waste, thereby reducing the emissions and helping to protect the environment.

Main advantages

- Technologie capable de traiter une grande diversité de déchets dédiés, spéciaux solides, liquides ou pâteux

- Destruction complète des déchets dangereux par procédé thermique à haute température

- Souplesse de fonctionnement

- Fiabilité et longévité des installations (plus de 20 ans)

- Possibilité de production de vapeur pour besoins industriels ou la production électrique (ORC)

STATIC INCINERATOR WITH SEVERAL FLOORS AND SEPARATED POST-COMBUSTION

STATIC INCINERATOR WITH ONE FLOOR AND BUILT-IN POST-COMBUSTION

STATIC FURNACE

Outlet temperature: between 900°C and 1 100°C during the cleaning phase

Lined with refractory bricks, 400mm thick

Indicative characteristics for 4.0 t/h of solid waste and 1.0 t/h of liquid waste

- Width : 4500 mm

- Lenght: 13m

Post-combustion chamber

Compulsory connected to the static furnace, it treats polluted liquids and ensures the complete combustion of gaseous residues from the Static furnace.

Outlet temperature: 900°C and 1 100°C during the cleaning phase

Lined with refractory bricks in layers

Indicative characteristics for 3,6 t/h of soggy and liquid waste

- Length 5,8 x 6,2 m

- Hight 20 m